I've read articles explaining "Camber thrust" theory but never seen any real world evidence of the effects of camber on a bike in a similar way that Bill Milliken did with his MX1 "Camber Car". Often wondered how to do that but couldn't think of an easy way until the 2WS Demo Bike construction was almost done. Replacing the 2WS Demo Bike forks with 30 degree cambered forks, but with only one wheel steering, was fairly easy.

The cambered tire contact patches had to go in precisely the same place relative to the steering axis and with identical ride height. The constant radius (26mm) of the Maxxis Hookworm tread profile was very helpful with getting the geometry right in the jig and for maintaining contact patch symmetry.

So why bother? Explanations I've read (Or watched on YouTube) were rife with tenuous analogies, handwaving, markerboards, cone shaped objects, inappropriate tires, etc... NO real-world tests with camber on bike tires. The science of single-track vehicle dynamics shouldn't depend on tenets of faith and devotion.

Belief is imperative that a rolling 3D bike tire surface interacting with a stationary 2D road surface does . . . what? Bike tire diameter differential at the contact patch is fixed for any given tire, yet it will track with the same input over an infinite variety of corner radii and lean angles. And if it rolls straight because of equal diameter on either side of the contact patch, it shouldn't go straight gracefully when bike tires are cambered.

Not all single track vehicles have tires yet they still steer and handle the same. Single track vehicles have been ridden with large round sawblades and ice skate blades - NO camber thrust there. The most basic single track vehicle is a simple disc with a sharp edge - roll it across a hard surface and watch roll along gracefully until it turns gracefully in decreasing radius circles as it slows until, fully depleted of grace, it falls down - NO camber thrust involved, is there?

Yes, it really messes with your head at first when you look down and see the front wheel in action - that must do something different, right? What is different: Tire scrub (Which was expected) and lateral displacement on bump (Not expected but easily figured out). Rolling resistance increased even more with right turns. Rolling resistance decreased a lot with left turns. As it rolls, the tire's leading surface moves to the left before it makes contact: Step shaped bumps would move each end of the bike over to the right. Wave shaped bumps would move each end of the bike in a right/left motion.

Otherwise, completely normal. The steering and handling was exactly the same. NO tendency to veer, dart, shimmy, weave, careen, squirm, yaw, crab, etc... Braking either/both wheels and acceleration was normal. It tracked effortlessly and predictably, turning either direction or straight ahead.

Ergo: NO camber thrust.

While this is obviously not an SAE level technical publication or doctorate level dissertation, the methods and results are clearly reproducible. As always, it is very satisfying to roll something finished out of the shop, test something unproven, and have an awful lot of fun doing it.

PS: Inquisitive of moto-heresy? Bike and associated components are for sale - email me if you're interested...

Took a little time away from the new racer project and made a cheap and easy to build electric 2WS demonstration bike. I've known about the effect of 2WS on lean angle for decades, but never effectively demonstrated it. The end of the video has frame grabs that illustrate the 2WS effects on lean angle and front wheel steering angle.

Numbers:

- Weight with battery 62 pounds.

- Wheelbase 53 inches.

- Head tube angle at both ends 0 degrees.

- Trail at both ends 1.4 inches.

- Weight distribution with rider 60% F | 40% R.

- RWS settings 0%, 50%, and 66%.

- Hubmotor 48V 1000W.

- Battery capacity 20 Ah.

- Top speed 24 MPH.

I've never tested 2WS beyond 50% RWS - was afraid it might become unstable past that point. But not knowing something is supposed to be good motivation to learn something rather than rationalize FUD - do the research! At 66% RWS, it worked far better than I expected - it never did anything evil, even if it felt weird at first. While good low speed behavior doesn't always correlate with good high speed behavior, good research results encourage development work.

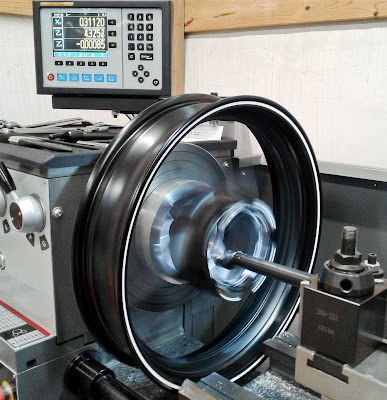

The rear hubmotor was sold as a front hubmotor for an electric bicycle "Pedal Assist" system - it won't go unless the rider is pedaling. No crank means no pedaling, so the sensor trigger ring was chucked in the lathe, bored out, and pressed onto the hubmotor bearing boss. The sensor bracket was cut down and welded to the fork dropout. It works very well - not sure how legal that is! The 3 speed settings give a maximum indicated 14, 19, and 24 MPH. After the motor controller is turned on and bike is rolled forward a few inches, it takes off from stops with just the throttle.

I wanted the steering ratios to be as accurate as possible. A simple jig that clamped around the fork crown made that easy. It only takes a few seconds to change the RWS settings by repositioning the link's rod ends on different bracket holes. Careful bracket placement made wheel realignment unnecessary.

The initial plan for observing changes in lean angles was to use a common digital speedometer and an old JVC action camera aimed to the outside of the turn and bolted to a welded-on frame bracket - low risk of inconsistent results with a consistent and repeatable perspective. But then the idea of using a Speedangle Apex lap timer (With lean angle indicator, GPS speedometer, and data logger!) sounded like an even better idea. Experience ended up proving otherwise - the Speedangle unit gave very inaccurate readings with 2WS engaged - even worse at 66% than 50%. It is otherwise a very nice unit, but obviously not developed for unconventional motion analysis. So back we went to the first layout: Consistent speed (15 MPH) over a consistent radius (42 feet) gave the consistent results needed. I can't tell you the lean angle difference measurements, but those differences are obvious.

While this is obviously not an SAE level technical publication or doctorate level dissertation, the methods and results are clearly reproducible. There's enough information and breakthrough potential here to get really excited about it all if you can comprehend the possibilities. Meanwhile, it was very satisfying to roll something finished out of the shop, test something unproven with better than expected results, and actually ride.

PS: Inquisitive of moto-heresy? Bike and associated components are for sale - email me if you're interested...

Got the frame far enough along to install the upper A-arms and dummy shocks (Half travel length). Next steps: Finishing the frame with a lot of triangulation and finishing the steering system. The lower suspension arm (Left side) is laterally located by Watt's linkages (Not shown) to the right side lower tube. Two wheel drive and two wheel steering in the 21st century requires a far different design approach - 19th century technology doesn't work.

Another surprise video - wasn't involved with the production - still glad to see it out there. Has the typical mix of enthusiastic comments and stupid comments:

Next one should be more fun when it's done - no other reason to do it...

Finally got to that stage of frame fabrication where I could prop it up and fit check it. Sitting on a bike project for the first time is an important milestone - it's no longer just endless work toward an impossibly distant goal - it's strong motivation to see it roll for the first time (Next milestone) and test ride it (Last milestone).

Normally, I tack weld the entire frame assembly together, fit check it during some stage of that, then finish weld it (Including capping open tube ends) when there's nothing left to add. This time, some tubes had to be trimmed, capped, and finish welded before continuing on with the next operations. So off the bench it came, work was done, and, well, there it is,

The primary frame structure is done now - time to finish connecting the dots with some triangulation. According to the scale, this frame looks like it will weigh just over half of the last one. The suspension is already done - still have to make the steering system before I have a finished roller. I have no idea when I'll reach that milestone, but it is that much closer to getting there.

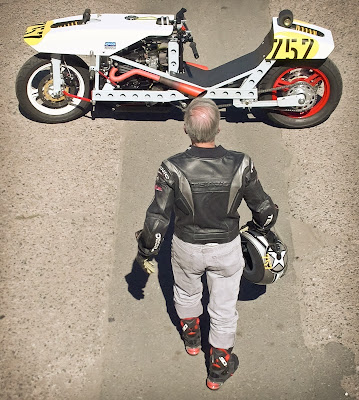

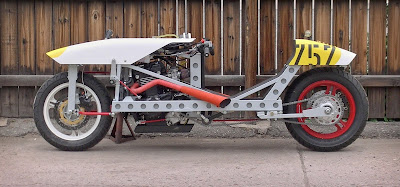

Hanging from my ceiling over my desk, for many years, was my first 2WS/2WD experimental electric recumbent bike. While staring at it, I wondered why a video wasn't produced as soon as it was done. Then it hit me: It was built and ridden about 3 years before YouTube was launched! It was designed and built almost a quarter century ago! It also hadn't been ridden in 8 years - time to take it down, dust it off, and give it a fresh set of tires and batteries! The paint exhibits some wear and tear, but, well, so do I:

The inspiration behind this concept was written almost a third of a century ago - articles by Kevin Cameron about breakthroughs that could overcome performance limitations of current race bike design: Beyond Telescopic Forks, Cycle, January 1987 and Two-Wheel Steering, Cycle World, February 1992.

...and that's all of it. So far...

Taking the first 2WS/2WD out for a ride was very satisfying - the real world provides far better answers than the entire media (Social or otherwise) to the question: "I wonder what it's like to ride?"

The 2WS/2WD system for the next racer is assembled and on the bench!

The engine is out of the donor bike. It is smaller in every dimension, 5 lbs. lighter, and over twice the horsepower of the EX500 engine in the last racer.

The engine goes up on the bench as soon as the left side gets cut down - have to make room for the front wheel drive belt by removing the stator (Done), turning down the alternator rotor (Done), and cutting down the alternator cover (Done). The starter remains.

Speaking of engine weights, a number of engines have gone across my shop scale over the years:

Kawasaki KX500 - 60 lbs.Kawasaki EX500 - 126 lbs.Ducati 999S - 153 lbs.H-D 883 4 speed - 185 lbs.H-D 1340 Evo 5 speed - 215 lbs.Honda CBX - 215 lbs.KTM 890 - 121 lbs.

This is the first bike project of mine where the frame wasn't built first. The 2WS/2WD system was challenging enough to get the drive and suspension designed and built first - what a friend calls the fancy bracket which holds it all together (The "Frame") designs itself and gets built next. Building the frame last delays that motivating milestone: Sitting on it for the first time and imagining what it must be like to ride while making silly engine noises.

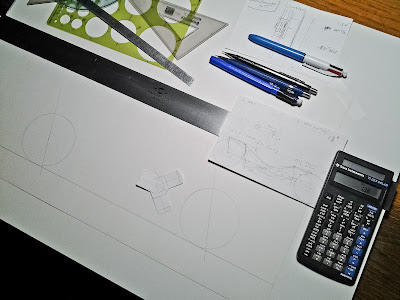

Watching a pile of components grow while hoping the TI-36X button pusher entered the right numbers so they'll all bolt together the first time is a little stressful. Going from idea to geometry to drawing to fabrication to final assembly to testing is an intense path to travel; creation and motion makes life more like living. Sometimes work, no matter how fun the results might be, is still work - the potential reward sometimes seems eternally distant to the point of despair. Burnout!

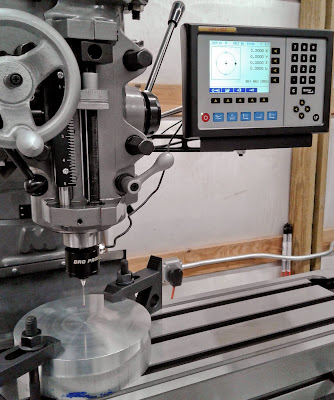

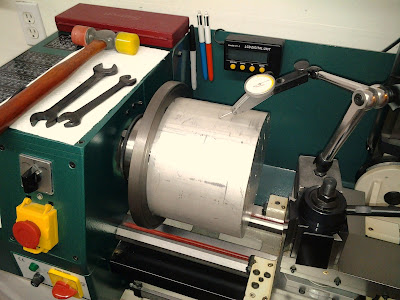

After a demanding day at work, even more work out in the shop doesn't sound like my idea of fun. But why not just take a break, go out to the shop, crank up the Bluetooth speaker, and relax? Oh look - there's the "To Do" list on the markerboard - it never loses arguments. Might as well go clean off the mill table for the next job since we're out here. Then square up and bolt down the vise. Go ahead and center that part, stick the probe in the spindle, and zero out the DRO - that forgotten playlist on the speaker is far from over and I forgot how much I liked that - I hope the neighbors like it as well. Since you know where you are, pilot drill it, then get the boring head in the spindle and the boring bit trued up. I'll bet that first pass cuts right! Hey, the calculator says there's only 9.1 passes left! Now get the identical part for the other end loaded for tomorrow, but why not give it a head start this time? Oh look - that one's also done now! Now I get to do one of my favorite things: Erase that nagging line from the "To Do" list off the markerboard. Winning!

And that is happening a lot more now. And when the frame gets done, I'll still get to sit on it. This time, testing it will happen a lot sooner after that....

When the decision was made to build the last racer, the first 3 thoughts went through my head:

- This is going to be a lot of work.

- This should be a lot of fun when it is done.

- This is going to generate a lot of stupid comments.

2) It was. More fun than anybody else knows!!!

3) Far less than I expected in the real world - virtually none, really - then there's Facebook:

- Low CG motorcycles are hard to balance - ever try balancing a short broom?

- That's just a copy of the Gurney Alligator!

- You'll die if you crash or run into something!

- All those ball joints and rods kill steering feel!

- The rider can't see where he's going on the track!

- Can't properly stand on the pegs whilst riding over bumps!

- KANEDA!

2) Considering the liquid cooled twin cylinder engine, 2 wheel steering, no steering head, virtual hub center steering front suspension, remote mount handlebar, and reclined seat and rider position, there are more differences than similarities. OK: The 'Gator was the only recumbent motorcycle to get any decent coverage in this country from the legacy motorcycle media.

3) Crashed at medium speed early 2013 - crashed at high speed later 2014 - didn't die either time, as far as I can remember. And if you are colliding with stationary objects at the track, well, you're doing it wrong - roadracing in this century is not for you.

4) No, they do not. Or at least they don't if teflon lined rod ends are kept out of the system. Even quite a bit of play is better than a little bit of binding - the play will only be noticeable when parked - while cornering, there is a load on the handlebars (That's where feedback comes from!) taking up any play that might exist, leaving that crucial front end feel completely intact.

Front end feel comes from changes in the steering load - a little change means a lot. NOTHING kills that feel more than having the rider's weight on the handlebars while trail braking. With a recumbent motorcycle, the handlebars are just that - bars for the hands - the level of feedback from the front end is amazing if there is enough trail to provide it. Hub center steered front ends often need less trail for stability, which also makes the steering lighter, but that also reduces front end feel - something too often blamed on "All those linkages".

Another change in perception comes from the effects of stiction - a binding telescopic fork functionally feels rigid and "Transmits" feedback very clearly. A rigid fork also loses traction very easily. What too many perceive as "Signal" from the front end is actually "Noise". It is too easy to confuse the absence of noise with a loss of signal, when in fact, the lowest level signals were always lost under a high noise threshold.

Speaking of feel: Nothing else provides a better level of feedback than a riding position that spans the wheelbase - any change in traction and/or yaw shift is immediately felt.

5) Yes, my line of sight while riding straight and level is quite a bit lower than usual - yes, that changes one's perspective quite a bit - one gets over it very quickly with some seat time. But when leaned over, my line of sight is no lower than usual - look at how high the rider's helmet is from the track when he's dragging his elbows. If you ever need to sit up higher to see where you're going on the track, again, you're doing it wrong - roadracing in this century is not for you.

6) Functional suspension works better. And if that's not good enough, try riding on a paved racetrack instead.

7) Akira references really are fun! A friend made me really cool race team logo from "Bartkira" many years ago. The movie bike is wonderful art for fictional anime/manga, but, sadly, terrible design for the real world. But unlike too many hopelessly unfinishable Akira copies, my old racer was finished, tested, raced, and it worked.

Yes, I terminated my Facebook account several months ago. The Venn diagram for "People who talk a lot on Facebook" and "People who do a lot in the real world" has virtually no overlap. Only in social media is ignorance considered a uncorrupted form of wisdom. I prefer the real world. Try it, you'll like it.

One area I find a great deal of enthusiasm online comes from what I call the "Enthusiast Motorcycle Media" (As opposed to the "Clickbait Motorcycle Media" and "Legacy Motorcycle Media). More about all that happy stuff was published in a fun interview at Bike-urious - thanks, Abhi!

The racer has spent almost 3 years in the workshop, welcoming me every time I walk in the door. While it still is an unusually amusing sight, it isn't doing me a whole lot of good. The original plan of parking it in our living room seemed like an increasingly bad idea - a split level mid-century house, oddly enough, isn't optimized for motorsports displays. So, what about loaning it to a museum, so others can marvel/point and laugh at it? Why not? So a call was made to a Big Motorcycle Museum in Alabama - the word "Loan" didn't get finished before the other end of the line snapped back a snotty "We only accept donations - on OUR terms - NO LOANED MOTORCYCLES!". Oh, really: Not at my current net worth.

So the next call went out to the nearby St. Francis Motorcycle Museum. I asked if they were interested in displaying an experimental homebuilt roadracer. They said they would be interested if it is something different - is it . . . different?

Last night, the racer was loaded up in the van and rolled into their front door this morning. Would the spot between the ELR and unmolested R90/6 be OK? Oh, yes.

The museum opened up in 2016 - it isn't on the usual internet lists of motorcycle museums, or at least not yet. It is run by enthusiasts - and it shows. No idea how long my old racer will be there - if all goes well, I'll retire not too many years from now and it'll end up in someone else's living room, office, or . . . museum.

In the mean time, the next racer is in that stage where lots of work has been done, but it doesn't look that way - just an increasing spread of small parts waiting to become one big part. Boring, indeed.

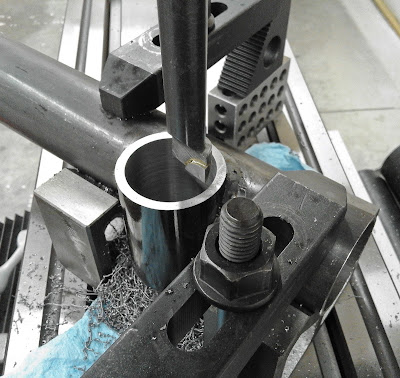

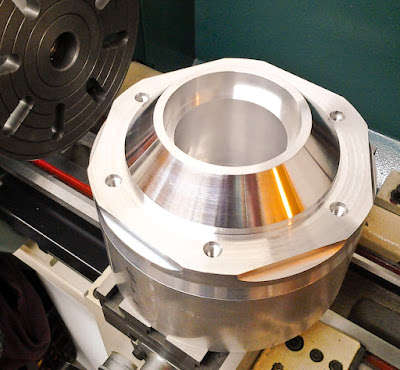

That's one of the wheel uprights - one of two welded assemblies of 6 machined tubes each that gets finish machined after welding. It is far more work than the similar bolted-up solid aluminum one at the back of the last racer, but the new ones weigh less than half and look a lot better (Yes, that matters!). A fiber wound forging would look even better and weigh even less - not happening with the resources at hand. The last racer's rolling chassis assembly weighed 290 lbs - if the next one can get down to 170 lbs, we'll be in great shape.

When the decision was made to build the last racer, the first 3 thoughts went through my head:

- This is going to be a lot of work.

- This should be a lot of fun when it is done.

- This is going to generate a lot of stupid comments.

2) It was. More fun than anybody knows (Test rides were offered, but . . . never meet your heroes...).

3) Far less than I expected - but everyone knows how Facebook really works:

Frequently Posted Comments (FPC):

- Low CG motorcycles are hard to balance - ever try balancing a short broom?

- That's just a copy of the Gurney Alligator!

- You'll die if you crash or run into something!

- The rider can't see where he's going on the track!!!!!

2) Except for the liquid cooled twin cylinder engine, 2 wheel steering, no steering head, virtual hub center steering front suspension, remote mount handlebar, and laid back seat and rider position, yeah, man - no difference at all - like total rip-off, dude...

Most of those 'Gators are in museums or collections now - none of them were club raced on the track. That said, it was the first and last recumbent motorcycle to get any decent coverage from the legacy motorcycle media, so that's all that many understand. That has to change, eventually...

3) Crashed twice - once at medium speed, and again at high speed - didn't die either time, as far as I can remember. And if you're at risk of colliding with stationary objects at the track, well, find another sport - roadracing is not for you.

4) Yes, my line of sight while sitting upright is quite a bit lower than normal - yes, that changes one's perspective quite a bit - one gets over it very quickly with some seat time. But when leaned over, my line of sight is no lower than the normal - look at how high off the track the rider's helmet is when he's dragging his elbows. If you need to sit up higher and see where you're going on the track, again, go find another sport - roadracing is not for you.

I've found the best response to such nonsense on Facebook was to leave it - far too much noise - no real benefit to anything I'm doing in the real world, where I prefer to live, work, build, and best of all, race.

One of the big challenges for the next racer was building an engine with my own crankcases. The built and fully developed engine was expected to weight under a 100 lbs and produce over a 100 hp. The initial engine build is the relatively quick, cheap, and easy part - the development is where time, money, and work can be challenging. All of that isn't entirely necessary any more - the recent KTM 890 engine fills the design requirements reasonably well. A KTM Duke 890 has just rolled in the shop, and a lot of the previous donor engines and parts have been sold to help pay for some of it. This project was about a year behind schedule - this moves things forward quite a bit! Absolutely no changes are required for the rest of the motorcycle. A 4-stroke twin provides greater opportunities for racing in clubs that accommodate real purpose-built race bikes.

The 2-stroke engine design that I had in mind would still be a good project and would have made for a good story, but other than being a different way of doing the same thing, it wouldn't have done anything better than the above 890 engine. That said, while lap times and all that don't care about "The Story", the most intriguing racing motorcycles have at least one good Story behind them beyond the score chart. I don't believe that racing is strictly about the racer and not the motorcycle, otherwise we could just dispense with the expense of those unnecessary machines and just race without the burdening the racer with equipment: Running barefoot and naked! No, that's really not my idea of fun, either

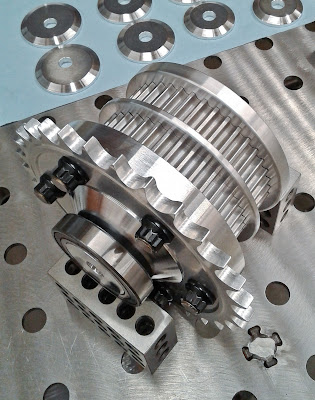

Oh yes - that 2-stoke engine: Modern casting methods could result in a far lighter engine than any backyard foundry can render. Something simple, cheap, and easy to work on with over 100 hp and under 50 lbs will take a real design and development team and facilities - it could still happen, but it won't be one man's story.In the mean time, work is still in progress. Ever wonder what a 2WD motorcycle differential looks like? The inner (Rear wheel) pulley is solidly mounted to the spool - the outer (Front wheel) pulley is mounted to the spool with a one way clutch bearing. The spool itself mounts in the drive arm and is chain driven by the engine.

Before tearing down the KTM, it'll require some break-in mileage. It is the first "Normal" motorcycle I've ridden since race school, early 2012. It seems like a shame to take apart a perfectly good bike (I really like the Duke 890 an awful lot!), but the next racer should make it all worth it!

According to the social media single track vehicle dynamics authorities (Do-Little Talk-a-Lots and Stale Cliché Curators, the lot of them), I'm doing everything wrong! They don't know what I'm doing, so clearly I must not know what I'm doing, either! Appeal of authority gets far more approval from the uninvolved!

Modern motorcycle design has evolved itself into a corner - they can't go accelerate or decelerate any harder without flipping, or corner any harder without running out of clearance. Any changes to one or more areas to improve one aspect will result in an overall loss of performance. Tires are optimized to accelerate or brake, not both, leading to cooling events. Suspension has to be optimized for load transfer extremes. All the above leads to both slow roll response and high polar inertia about the longitudinal axis. And that results in terrible aerodynamics. ALL of the above problems can be successfully addressed IF you discard the original configuration and derive a functionally superior configuration that isn't recognizable.

Here are the old problems (And causes):

- Stoppies (High CG, short WB)

- Wheelies (High CG, short WB)

- Lean angle limitations (Oversized rear tires)

- Roll rate limitations (High CG)

- Suspension sub-optimization (High CG, short WB)

- Tire sub-optimization (High CG, short WB)

- Aerodynamic sub-optimization (High CG, short WB)

- Long WB, low CG, linked brakes

- Long WB, low CG, 2WD

- 2WS, appropriate tire selection

- 2WS, low CG

- Long WB, low CG

- 2WD, 2WS, linked brakes, long WB

- Long WB, low CG

1. Pretty obvious, really. If load transfer under braking can't flip the bike, then there must still be some load on both tires. The lower the CG, the less load transfer, and the more both wheels will do the work. It also means that trail braking will be a lot more effective as the tire's loads transfer from braking to cornering.

2. Also obvious. Pretty much opposite of the above, just a lot more difficult to implement with internal combustion engines. The solution to that problem will be addressed later...

3. Not obvious, at least with the 2WS part. The tire part ought to be obvious: With 2WD and linked brakes, a big fat rear tire is no longer necessary or even desirable. A narrow tire at both ends provides enough footprint area.

With 2WS, the cornering forces become much less perpendicular to the CG, reducing lean angle quite a bit (Simple trigonometry, if you must). If 2WS were taken to an extreme, changing the vehicle into a purely 2-tracked vehicle known as a "Di-cycle", NO lean angle involved in cornering. That isn't practical for obvious reasons, but steering the rear wheel in the same direction of the turn at any ratio much over 25 % contributes to the same effect, thus reducing lean angle.

Both the narrower rear tire and 2WS effects greatly offset the negative effects of lower CG on lean angle. No, this isn't in any of the books. Yet.

4. Not as obvious as it ought to be, sort of: Obviously, the reduced polar moment both makes changing lean angle easier and. importantl, makes stopping changes to the lean angle easier. Less obviously, the lower the CG, the greater the lean angle changes with displacement of the contact patch relative to the CG. 2WS normally wouldn't help at all with a high CG in that regard, since most of the effort in counter-steering is exerted in overcoming wheel inertia - but with the lower CG and increased displacement effect, countersteering becomes a LOT faster with the same effort.

5. Extreme load transfer is no longer happening, which means that a suspension range and rate to accommodate those extremes is no longer required. And with less suspension travel comes less sag under cornering, thus improving ground clearance and allowing an even lower CG. Lower CG and long WB, and less travel also means drastically reduced chassis pitching to bump response, acceleration, and braking, resulting in far greater chassis stability. And greater chassis stability reduces the appeal of pointlessly playing around with dive/squat/"Anti(x)" geometry.

6. With 2WD, linked brakes, 2WS, low CG, and long WB, both tires are working all the time. There are no "Break times" for cooling down then requiring warming back up to optimum temperature. And since extreme load transfer isn't happening anymore, much lower tire pressures (With the obvious benefit of a larger footprint) are both possible and desirable without incurring stability and control issues. Having interchangeable front and rear wheels and tires is a welcome benefit. I doubt that existing tires are close to optimized for such implementation, but the choice of racing slick tires with different compounds and carcass stiffness is a huge help.

7) Obvious: Much lower frontal area results in less drag. Really. No kidding.

The rationale (And obvious physics) behind all 7 points above have guided the design of my next racer. All 7 points are necessary, if not convenient, to work. I'm not going to go any faster by attempting to minimize existing problems with current configurations - I want to go a LOT faster by completely eliminating those problems with a completely new application.

No, not all 7 points need to be applied to less demanding recumbent (AKA, "FF") motorcycles, any more than the old van I use to haul the racer to the track needs to be optimized for track use, either. And, no, I don't expect said social media authorities to accept them either - they are too invested in rationalizing their lazy design choices and gossiping - I'm never going to see any of them or their work at any race track.

So, what else is it good for? Well, electric motorcycles exhibit a LOT of functional shortcomings relative to their internal combustion relatives. Horseless carriages were terrible cars - gasless motorbikes make terrible motorcycles. But a lightweight streamlined low CG, 2WS, 2WD one would solve range, speed, cost, packaging, and weight issues while providing uncommonly high comfort, performance and protection - right now. Truly effective regenerative braking is only possible with that configuration. With 2WS and 2WD - and smart steering control - it would be possible at a stop to steer both wheels to the side to some degree and balance the bike without human intervention - no dippy outriggers necessary. And park it by lowering it all the way onto an integrated stand. Wind gust response would be counteracted by that smart 2WS. Etc... - the design and dynamic potential is mind-blowing. None of that is in the books, or gossiped about by said intellectually paralyzed "Social media authorities". Yet.

In the mean time, work is progressing nicely on the next racer. Got questions? You know how to reach me. Got gossip? You know where to go.

Posts here will be as frequent as usual (I.e., seldom) - progress pictures will get posted on My Instagram page.

After the Quail event, Jason Cormier at Odd Bike asked me for an article on the racer project and some of the background - that gave me a good excuse to explain a little how I got to this point and a little more about where I'm going. It's been a fun experience so far, which made it a lot of fun to write. Thanks, Jason!

All of the custom ordered parts have arrived: Connecting rods, crank pin, and hybrid Kawasaki KX500/Ducati 999 primary gear (All from England), Poly Chain GT 8 mm pulley stock (For final drive), and 56 mm Lectron downdraft carburetor (For feeding 706 cc crankcase displacement). And then there's the one and only part I just pulled off the last racer that goes on the next one - it's a part that's getting a lot harder to find.

The engine casting will have to work well with the 2WD final drive arm, so those get designed and built together - after that, the frame and 2WS system pretty much fall into place. The big plan for the bodywork is to have as little as possible, as simple as possible, and as cheap and easy to replace, vinyl wrap, and install as possible - wasting time and money on ugly over-styled plastic that gets vinyl wrapped anyway seems really stupid to me, especially for a racer, where bodywork is considered a consumable item, like tires, safety wire, collarbones, etc...

More later...

My favorite thrill is pinning the throttle after the apex of T3 at HPR, especially with an untested bike. My second favorite thrill is getting an idea out of my head and turning it into a design before making it real, loading it into the van, and taking it to the track. The next racer is into that "Second favorite" stage. The details are a lot different than the first racer, with a few exceptions. The shocks will end up in the same area, and the upper A-arms and single sided steered upright will return at both ends (With vastly lighter and better looking design and fabrication). I'm really excited about the design of the lower suspension arm - it is VERY exotic and unique (One arm for both wheels) - it solves all of my prior 2WS/2WD design nuisances and headaches.

Another good thrill is having a photo pass for MRA events and shooting video. While nothing beats the view of the race from a race bike, being able to wander around the track and scout out vantage points for capturing the action is about as close as anyone else can get. A lot of my footage made it into the MRA's Award Banquet video - thanks for the credit!

Getting the shop together and tooled up is still in progress. All of the lighting and outlets were removed and replaced. A heater should be installed very soon. Real machine tools have been moved in. As always, good help is necessary for rigging heavy machines!

There's a LOT of work in the shop to be done in 2019. And MRA racing action to shoot at HPR with a new camera this upcoming season well.

T3 awaits...

Top video: Jeremy Alexander

If all goes well, I'll race at HPR later in the season. Then that bike retires in the living room, and I get rolling in the shop on the next racer...

The next racer is still in the phase before "Connect the Dots" that I like to call "Collect the Dots". While working on some of the design headaches involving a belt drive primary connecting the KX500 engine to the 999 transmission, I wondered if there was a remote chance that a 999 primary drive gear system would fit, since the KX500 primary gearing is terrible for roadracing. The KX500 stroke is a lot higher, so I assumed it wouldn't fit. With the help of a few parts on hand and a few more cheap parts from eBay, the answer became obvious:

The drive side of the crank, 999 primary gear, and KX500 primary gear were promptly boxed up and shipped off to a gear making specialist in England, where a few hybrid 999/KX500 primary gears will be made. Longer connecting rods will also have to be made (The original rod/stroke ratio is not optimal for a higher revving roadracing engine). A longer crank pin will be required for my counterbalancer/inlet valve/supercharger (Yes!!!!) design. Patterns and castings will have to be made for the engine cases. Then those cases have to be machined. It'll be a lot of work, but it should be an a lot of fun.

And then there's the rolling chassis...

And then there's the ultimate question that I can't wait to find the answer: How exciting will it be to exit Pit Out, tip it hard into T3, then pin the throttle?

Glad to be alive.

The improvement in steering and handling boosted my confidence enough to register for the MRA's final HPR event for the season.Then I got a job offer in the High Plains region of Colorado. Race registration was then cancelled, due to focus on other matters. Time to sell my Englewood home (And 8' x 8' shed) and move into a much better home (With a 30' x 50' insulated 240V workshop and 27' x 31' garage)! There's a lot of romance and mythology about building bikes in sheds - it was a fun and challenging way to start - but the Rohorn Industrial Complex has outgrown that.

There is a lot of work to be finished to the shop (And money to be spent on machinery) before a lot of work gets started on the next racer. But getting this far is a huge step forward.

The rest of 2017's involvement with motorcycle racing was behind a video camera at the MRA's HPR events. Time spent at the track, as close to the action as I could get, with an old JVC GY-HM70U and GC-PX100 was an excellent experience. If you love motorcycle roadracing and want to get involved and up close without actually racing, I highly recommend working as a Corner Marshal for a season, then getting a media pass and shooting photo and/or video. I shot most of the off-bike video content in the 2017 MRA Awards Banquet video:

- Give up and find other things to do. There are Other Things.

- Design and build a competitive club racer. Not doing it would be a waste of opportunity.

- 17 x 3.5" wheels with split hub center steering at both ends. If I can steer the rear wheel, I can drive the front wheel. An overrunning clutch to the front wheel will eliminate the need for a differential. Initially, entirely machined wheels were planned, but previous generation R1 front wheels are ideal - they are very light for a production wheel, and the hub area is big enough to bore out and install a smaller universal joint in the center with a lighter machined hub. A cheap damaged wheel verified that it will work.

- 500 single 2-stroke power, with a combination counterbalancer/intake valve (My design), and a 6 speed transmission with a dry clutch. A KX500 engine (On hand) will provide most of the mechanical parts, a Ducati 999 engine (On hand) will provide most of the transmission and clutch parts (Similar to the Tul-Aris set-up), and a foundry (Not on hand - yet) will provide the cases necessary to make it all work. That will be a lot of work, but it should make a lot of power for a very small engine, with much less maintenance, tuning work, exhaust fabrication, and cost than a multi-cylinder engine.

- Very narrow triangulated steel tube chassis. Exotic construction techniques were studied with a lot of enthusiasm, but none of them had any practical appeal. The ergonomics of the first racer were excellent, as viewed from the side, but the hands, knees, and feet need to move a LOT closer together to improve safety and aerodynamics.

When? Not soon enough....

Yes, steering geometry matters at the rear wheel as much as the front. A LOT of work was done to determine which geometry works and which doesn't. Instability from weaves, and speed wobbles with just the rear wheel, is no fun. That hasn't happened to this bike, but has happened with the electric one.

The drum brake rear wheel from the EX500 worked very well for this experiment. It is red because the donor bike came with a parts bike that had red wheels - no clever or creative aesthetics involved. The wheel was sent to Kosman Specialties to have the hub bored out back in 2009. That was the only machine work for this project that I didn't perform, since the wheel didn't fit in my lathe/mill.

The rest of the machined parts came out of my Grizzly G0516 lathe/mill. I got a lot of good parts out of that machine, but it has since been sold. The next racer will need more serious machinery located in a serious shop, rather than my kitchen (Seriously!).

Yes, it is a lot of fun to show up with an exotic motorcycle, but racing is about how you ride, not what you ride. Other than some minor bodywork restoration and steering column modification, there's nothing left to do except ride it. And work on a completely new design based on the same configuration and very little else.

After those first 2 laps and an hour or so of inspection (No loose or missing hardware! No adjustments needed at all!) and introspection (Do I really want to do this anymore? The turns are where I remember them 2 years ago, but where did my sense of timing go? Do I really want to go back out there?), the doubt, confusion, and overwhelming sensory input that race tracks can provide somehow evolved into that powerful feeling that somehow gets helmets and leathers on without thinking: Must! Go! Back! Out! That is a really good feeling!

The next 2 laps went a lot better. Even though I haven't ridden it (Or anything else) in 2 years, I still instinctively slid over on the seat to hang off into the corners. That isn't necessary anymore, since the 2WS system reduces lean angle a lot more than hanging off. The linked braking system is a huge improvement over the old system. Hard braking is drama free, as is trail braking into corners. Great brakes and steering systems might not sound too useful when they aren't being used properly, but they do wonders for improving confidence in the bike.

The last 3 laps were just a lot of fun trying to use what I learned earlier in the day. No lap times were recorded, but I'm looking forward to learning a lot more. The last MRA race of the season is at High Plains Raceway, 17-18 September.

The racer was finally assembled enough to fire it up and ride it this afternoon. The test ride was only a 1st gear lap around a nearby parking lot, but it went very well - well enough to look forward to a test & tune day at the track. And if that goes well, we go racing.

Some details need finishing, like securing the wiring and lots of safety wiring. The nose section was structurally repaired, but not cosmetically finished - I didn't want to delay the testing any further.

This has taken a lot longer than expected, but it has been worth the time and trouble.

No, it won't break any lap records or even get close to the podium, but I'm confident that the next and better racer will easily do that. The next and better racer will share the same configuration and fundamental dimensions, but little else. A lighter steel or aluminum ladder frame would be easy to make, but it still wouldn't be light enough. Exotic motorcycle frame design and construction techniques really don't transfer to this configuration, but there sure seems to be a lot of potential with advanced Formula car methods. Exotic fabrications using aluminum honeycomb sound amazing, even if those are also obsolete. What could be more intriguing that bringing motorcycle construction from the biplane era to the early Cold War supersonic jet era?

Frame design can be described as a structural connect the dots puzzle. It is fun to imagine really exotic solutions, and even more fun to talk about. Material expense, repairability, maintenance access, and ease of fabrication reduces the fun quite a bit. The solution that increases the probability of getting on the starting grid, going faster, and finishing ahead is the most fun.

Much of the trouble getting any work done on the racer has been the result of having a screw loose. No, that isn't comfortable. That is also getting removed soon! Progress on the racer should happen a lot faster afterwards. Faster is always better.

See you at High Plains Raceway soon....

More power with potential for a lot more power, a lot less weight (Goal: 265 lbs), a much narrower rider position (Much more aerodynamic and safer as well; the rider's squishy and crunchable bits go inboard the frame's perimeter this time), and loads more traction sound like my idea of fun. If all goes well, 2016 will see the current racer back on the track and construction started on the next racer. No idea what year it will be finished.

By the way - ever compare a four stroke street bike wiring harness to two stroke race bike wiring harness? Wow!

Oh, yes - the four stroke engine design can wait for another year. Or decade. It is still pretty neat...

While 2014's racing results were dismal, I'm still very optimistic about lowering my lap times a lot and picking up a few places. Not getting lapped would sure be cool, even if I do learn a LOT from the fast racers. And if you think watching them from the stands (Or better yet, while cornerworking!) is exciting, imagine the view from the track! But there's much to work on, on both my riding and the racer, before better finishes happen. It'll never get on the podium; that's for the next bike with a better rider.

Which means that, yes, I should be working on the racer instead of hypothetical engine models. Crash damage needs to be repaired, and that new rear suspension system still needs finishing and installation. I'm still hoping to have it done before the end of the 2015 racing season. But my biggest source of enthusiasm and motivation is the next racer; this racer has given me the confidence to make it worth the time, trouble, and expense. In the mean time, the door that leads from my desk to the shed has been upgraded to lower my house exit times by at least .2 seconds. No chatter problems, either.

I'm very happy to report that my foot is healing rapidly. The big goofy post-op boot has been off since early November. The crutches haven't been touched since the Christmas holidays. The cane only gets used on evenings of rougher days and to help make a point while yelling at kids to get off my lawn. I'm just left wondering whether or not my right foot will need a racing boot that's 3 sizes larger than my left foot. Either way, it would be a shame not to find out this year...

Top photo: Jim Browning, Rocky Mtn Photos