After the Quail event, Jason Cormier at Odd Bike asked me for an article on the racer project and some of the background - that gave me a good excuse to explain a little how I got to this point and a little more about where I'm going. It's been a fun experience so far, which made it a lot of fun to write. Thanks, Jason!

All of the custom ordered parts have arrived: Connecting rods, crank pin, and hybrid Kawasaki KX500/Ducati 999 primary gear (All from England), Poly Chain GT 8 mm pulley stock (For final drive), and 56 mm Lectron downdraft carburetor (For feeding 706 cc crankcase displacement). And then there's the one and only part I just pulled off the last racer that goes on the next one - it's a part that's getting a lot harder to find.

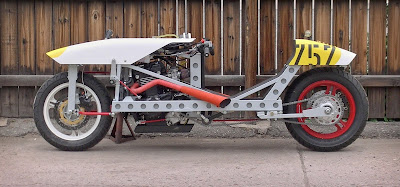

The engine casting will have to work well with the 2WD final drive arm, so those get designed and built together - after that, the frame and 2WS system pretty much fall into place. The big plan for the bodywork is to have as little as possible, as simple as possible, and as cheap and easy to replace, vinyl wrap, and install as possible - wasting time and money on ugly over-styled plastic that gets vinyl wrapped anyway seems really stupid to me, especially for a racer, where bodywork is considered a consumable item, like tires, safety wire, collarbones, etc...

More later...

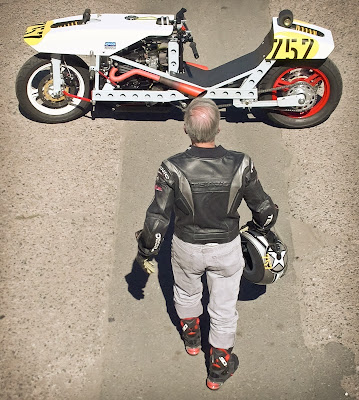

My favorite thrill is pinning the throttle after the apex of T3 at HPR, especially with an untested bike. My second favorite thrill is getting an idea out of my head and turning it into a design before making it real, loading it into the van, and taking it to the track. The next racer is into that "Second favorite" stage. The details are a lot different than the first racer, with a few exceptions. The shocks will end up in the same area, and the upper A-arms and single sided steered upright will return at both ends (With vastly lighter and better looking design and fabrication). I'm really excited about the design of the lower suspension arm - it is VERY exotic and unique (One arm for both wheels) - it solves all of my prior 2WS/2WD design nuisances and headaches.

Another good thrill is having a photo pass for MRA events and shooting video. While nothing beats the view of the race from a race bike, being able to wander around the track and scout out vantage points for capturing the action is about as close as anyone else can get. A lot of my footage made it into the MRA's Award Banquet video - thanks for the credit!

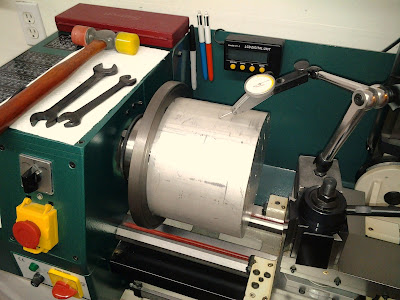

Getting the shop together and tooled up is still in progress. All of the lighting and outlets were removed and replaced. A heater should be installed very soon. Real machine tools have been moved in. As always, good help is necessary for rigging heavy machines!

There's a LOT of work in the shop to be done in 2019. And MRA racing action to shoot at HPR with a new camera this upcoming season well.

T3 awaits...

Top video: Jeremy Alexander

Hello…is this thing on? It’s been quite a while, but some of you may still be subscribed to the old RSS feed (is that still a thing?). If you do somehow find this post, I want to let you know that I just started posting again on the @bicycledesign Instagram account. I plan to update Instagram primarily going forward, but the Twitter and Facebook accounts will remain active too (mainly just auto-posting from Instagram).

Who knows… I may even start occasionally posting on the blog again too. I am sure that it would take quite a bit of time to rebuild the community after three years away, but I really do miss it, so the effort might be worthwhile. I don’t want to get ahead of myself though. For now. I’ll just see how it goes resurfacing on social media. I hope that you will follow along… and maybe even contribute some of your ideas and designs.

After ten years of blogging at Bicycle Design, it's time for me to move on. This post may seem a bit like déjà vu to those of you who remember my "final" post from February of last year, but this time I really do need to shift my focus to other projects and goals. I won't repeat everything that I said in that previous post, but I do want to reshare the first paragraph:

"It is hard to pinpoint the exact reason that I started this blog in 2005. I could say that it was to showcase the work of industrial designers in the bicycle industry, or to give students a place to share their bike related ideas and concepts, or maybe the idea was just to generate discussion and get people thinking about the potential of bicycles, and other types of human powered machines, to change the world for the better. Over time, I believe the blog has served all of those purposes, but when I quickly put together that first post over eight years ago (over 10 now), I wasn't thinking any of those things. The fact is, this blog was something I started one day on a whim, and I never imagined that it would ever last so long… or reach so many people."

At its peak, Bicycle Design reached over 100,000 readers per month, and I am truly grateful for each of them (each of you I should say). Since 2005, I have connected with many wonderful people through my blog, including talented designers who share my passion for bikes and human powered transportation. Thank you to all who contributed designs, participated in discussions, or just followed along. In the decade that this blog has been a part of my life, I have made new friends and learned more than I could have ever imagined. It has been a great experience, and I wouldn't trade it for anything.

Though I have really enjoyed sharing other people's designs for the past 10 years, I am looking forward to making time for a few of my own art and design projects (outside of the work I get paid to do). I also want to refocus on local bike advocacy issues, something that I was heavily involved with in the past, but have not had much free time for lately.

Going forward, I will continue to blog occasionally at JCT.design (pay attention to the "Bikes/Active Transportation" category where I plan to share a few of those personal design projects that I mentioned earlier). You can also connect with me on Twitter, Instagram, and a few other places on the web at @jctdesign. I do plan to continue updating the Bicycle Design Facebook page when interesting bike designs catch my attention, so follow along there if you don't already. Finally, I will contribute to Core77 every once in a while, so keep an eye out for me on that site too.

If you haven't been reading Bicycle Design from the beginning (or even if you have), I encourage you to look back at the 10 years worth of archives from this blog. Recently, I shared the The top 25 posts from 10 years of Bicycle Design, and I would consider that post a good place to start. Beyond the ones that have been the most popular though, there are many other great designs to explore in the 900+ archived posts. If you have been reading Bicycle Design for a while, perhaps you can share one of your favorite older posts in the comments for others to check out.

Thanks again to all you who have contributed, commented, or just read along over the past 10 years. You are the reason that this blog was such a great experience for me, so I really do hope you will keep in touch. You know where to find me.

//

By now, anyone reading this has likely seen the recent redesign of the Specialized Venge aero road bike. In the development of the new Venge, Specialized engineers used Altair's HyperWorks software suite "to analyze and improve the aerodynamic performance of the bike as well as optimize the weight and structural efficiency of the frame." Chris Yu, Aerodynamics & Racing R&D Lead at Specialized Bicycle Components, talks a bit about the design process in an interesting video on the Altair website. To find out a bit more, I asked Mike Barton, computational fluid dynamics (CFD) application specialist at Altair, a few questions:

Before we get into the Specialized Venge project, can you give me a brief over view of Altair and the type of work that you do?

Founded in 1985, Altair is a software engineering and consulting company headquartered in Troy, Mich. After three decades, Altair has grown into a global company specializing in optimization and simulation technology with more than 2,600 employees and 5,000 clients. Altair's software is used by a diverse set of industries, from auto, consumer goods, aero, ship design and rail to heavy machinery. The company uses its expertise and extensive work in various commercial and industrial sectors to help designers and product developers in a wide range of unique industries, including bicycle design, golf club design, and other sporting equipment such as shoes.

The company is best known for HyperWorks, its suite of computer aided engineering programs that helps engineers simulate and optimize designs for light weighting; noise, vibration and harshness; durability; crash and safety and more.

In addition, via its Partner Alliance, Altair provides customers with access to more than 35 additional software products to help designers and engineers develop and optimize their designs and products.

In addition to developing the Fluid Dynamics software that was used to optimize the aerodynamics of the new Venge, did Altair work directly with the industrial designers and engineers at Specialized throughout the design and development of the bike? Tell us a little about the process.

Specialized has been working with Altair for approximately three years to streamline its internal processes.

In the video on Altair's website, Specialized Aerodynamicist Chris Yu mentions that the CFD software allowed them to run problems quickly without perfect CAD, and that those virtual tests of frame shapes saved a lot of time and money over building multiple prototypes for wind tunnel testing. Once the first physical prototypes were tested though, how consistent was the real world data with the results from the software?

We did not receive verification metrics from Specialized regarding the accuracy of their simulations compared to wind tunnel estimates. However, Altair Engineering has conducted similar studies related to bicycle wheel performance with works published by the American Institute of Aeronautics and Astronautics (AIAA 2009, 2010 and 2011). The following publication details the CFD analysis of several bicycle wheels for a range of speeds and yaw angles compared to wind tunnel measurements. The analysis demonstrates good comparisons of the CFD simulation to that of the experimental data and also demonstrates unique flow attributes that were not captured during the wind tunnel testing.

A Comparative Aerodynamic Study of Commercial Bicycle Wheels using CFD

An Aerodynamic Study of Bicycle Wheel Performance Using CFD

A bicycle (even a pro-level racing bike) is slow compared to an airplane or F1 car. How does the lower range of speed for intended use affect the way that you optimize the aerodynamics of the frame?

Although the speeds at which a professional bicycle rider performs are considerably lower compared to an aircraft or automobile, the aerodynamic effects are still very much present.

Consider that the typical drag coefficient (a non-dimensional quantity that is used to quantify the drag or resistance of an object in a fluid environment) of a professional cyclist crouched on top of a moving bicycle ranges between 0.7 and 0.9. Assuming that the bicycle is highly efficient and the rider is aerodynamically streamlined, let's estimate the Cd to be 0.83 and his/her frontal area to be 3.2ft2. If we consider that the rider is traveling at 20mph he/she feels approximately 3.27 pounds force from the aerodynamic loading acting to slow him/her down. In comparison, a typical touring bicycle and upright rider with a Cd of 1.0 and a frontal area of 4.3 ft2 feels approximately 4.4 pounds force at 20 mph[i].

Based on the aerodynamic effects and accounting for minor differences in rolling resistance, the touring rider must put in approximately 27 percent more horsepower to keep pace with the professional rider and bicycle. Contrast that with a highly efficient automobile, like the Toyota Prius that typically has a Cd of less than 0.25 and a frontal area of 23.4 ft2[ii]. At the rider's speed of 20mph, the aerodynamic drag force is approximately 5.98 pounds force. Although the scales at which vehicles travel are considerably different, they are all influenced by the fluid they move through and this must be taken into account when designing for efficiency and speed.

What about the effect of the rider on the aerodynamics? Did the CFD software factor in the messy aerodynamics of a moving cyclist, or were just the aerodynamics of the bicycle considered.

The primary focus of the CFD conducted by Specialized was related to frame design. The design and simulation did not include effects of the rider, but this is possible with Altair HyperWorks AcuSolve.

Altair has developed a proof of concept simulation to demonstrate the lower torso and legs of a manikin pedaling. This analysis was conducted with the use of two Altair applications within a single simulation. The "Co-Simulation" combines the aerodynamic analysis of AcuSolve CFD with the multi-body systems analysis tool MotionSolve. This unique combination of tools allows engineers to analyze arbitrary rigid body motion and the effects of that motion on the surrounding air.

From the proof of concept simulation, Altair has determined that the air movement in the wake of the rider's legs and the bicycle's pedals significantly affects the aerodynamic loading on the rear triangle and rear wheel of the bicycle. The simulation demonstrates that the air flow in this wake is highly transient and pulses with a frequency higher than that of the cyclist's cadence. As each pulse of air collides with the frame and rear wheel a force acts to slow the rider down and may cause minor instabilities depending on the oncoming wind and direction of travel. Although somewhat minute, these forces can accumulate and will have an effect on the performance of the bicycle as it moves with the rider.

In addition to aerodynamic concerns, Chris Yu mentioned the importance of maintain structural targets while minimizing weight (to the UCI limit). Can you talk about the structural "ply by ply" analysis of the carbon and explain its relationship to the fluid optimization work? Were these completely separate problems to address, or were they analyzed and optimized together?

These were analyzed and optimized together.

What else was interesting about this project compared to the work that you typically do?

One of the more interesting aspects Altair contributed to for the work at Specialized was the use of out-of-the-box tools for advanced aerodynamic design. Specialized made use of the Altair HyperWorks Virtual Wind Tunnel to design the Venge frame. This tool gives typical design engineers the power to perform CFD simulation with little or no experience with fluid dynamics. This is in contrast with other CFD tools that require significant knowledge related to fluid dynamics, numerical analysis, and computer science.

The Virtual Wind Tunnel allows engineers to directly import CAD into the simulation environment, apply simply boundary conditions to the tunnel walls and part, define the flow conditions and run the simulation on a modest workstation. The results are reported automatically or can be custom formatted to meet specifications desired by the design team. The overall process in Virtual Wind Tunnel has been developed and tuned for engineers to use as a part of the entire design cycle. The aim is to give engineers the tools needed to create many more design iterations with less time spent on traditional prototyping and testing.

Footnotes:

[i] Whitt, Frank Rowland; David Gordon Wilson;MIT Press, 1982 (2nd edn), 377 pages

ISBN 0262731541, 9780262731546

[ii] http://ecomodder.com/wiki/index.php/Vehicle_Coefficient_of_Drag_List

//

//

For his final project in Mechanical Engineering at the Danish Technical University, Israeli born Danish citizen Kuba Szankowski designed a velomobile based on the classic Leitra design. He worked closely on the project with Carl Georg Rasmussen of Leitra, who "at eighty years young still builds and maintains all the velomobiles, as well as most any other aspect of the business himself." Prior to earning his degree, Kuba had worked as a bicycle mechanic and as an advocate for bicycle transportation in Jerusalem, so he wanted to build on those experiences and create a design that would introduce human powered transportation to a wider audience.

For his final project in Mechanical Engineering at the Danish Technical University, Israeli born Danish citizen Kuba Szankowski designed a velomobile based on the classic Leitra design. He worked closely on the project with Carl Georg Rasmussen of Leitra, who "at eighty years young still builds and maintains all the velomobiles, as well as most any other aspect of the business himself." Prior to earning his degree, Kuba had worked as a bicycle mechanic and as an advocate for bicycle transportation in Jerusalem, so he wanted to build on those experiences and create a design that would introduce human powered transportation to a wider audience.

He explains the idea behind his redesign of the Leitra:

"My main intent was to develop a bicycle fit for my mother (this is actually what I described in my exam, oddly enough)- a bicycle which cannot fall, with electrical assistance, which encapsulates the rider and protects by being visible and high above the ground. This, along with my own perspective of the ways with which the Leitra velomobile could be improved; these being the lack of ergonomic adjustability, its lack of customization for shared usage in a household and others brought me to my design.

I describe a bent aluminium chassis with a platform for a battery pack or other electrical components. The Leitra seat- a 900-gram fiber composite, originally designed by Carl G. by imprinting his bottom in the snow, was 3D scanned. The resulting file was used to develop the two seating positions, along with an adjustable crank mast.

Front view of seat upright and reclined

The vehicle is equipped with 24-inch wheels and a unique (to my knowledge) suspension system, which is a hybrid gas damper/ leaf spring. This is in comparison to the existing Leitra suspension, which is also unique (and field-tested!) double cantilever leaf spring, with about two cm displacement. What the existing suspension lacks is a dampening mechanism.

My analysis consisted mostly of Finite element modelling of the existing leaf spring and chassis. By having two models (the existing frame vs. the redesign), I was able to achieve what I called "independence from model discretisation". The viability of all this is of course subject for debate, and I welcome to share my findings with anyone interested.

In terms of this vehicle as a solution to the "blue ocean" problem, I envision three categories resulting; these are: the base tricycle, with no electrical assistance; a pedalec ("E-bike") class tricycle and an electrical vehicle capable of higher speeds (up to 45 km/h).

Kuba mentioned that he was interested to read the recent post by Karl Sparenberg of Windcheetah, whom he had the opportunity to meet, along with Mike Burrows, at the latest SPEZI festival. "I was happy to see a fellow engineer picking up the work of the masters and advancing it. I wish to find new audience for the Leitra, and bring these weird machines closer to my homeland and the world." Kuba will be presenting his design on October 30th at the 2015 Velomobile Seminar in Austria, so hopefully that will be the first step in making his design a reality. I am looking forward to seeing how it progresses.

(adsbygoogle = window.adsbygoogle || []).push({});

Subscribe to the email newsletter, and follow Bicycle Design on Facebook , Twitter , Pinterest , and Google + … and now on Instagram too!

I can hardly believe that it's been a full decade since I started this blog by posting one of my old marker renderings. Though I started with a few of my own sketches, what really kept me interested in blogging were the design submissions from others that I began to receive in those first few months. Over the past 10 years, readers have shared some great designs with the community here, so I want to take the opportunity to look back on this 10th anniversary of Bicycle Design and share a few of the top posts (Sunday was the actual anniversary, but close enough).

Because Bicycle Design was hosted on Blogger at bicycledesign.blogspot.com for the first 4 ½ years, very few posts prior to the February 2010 move are included in the Google Analytics data. As a result, this list heavily skewed toward the last 5 years, but with that caveat in mind, here are the top 25 Bicycle Design posts ranked by total pageviews:

1. The Smart ebike by Hussein Al-Attar

3. The design of SRAM Red 2012

4. Drymer: a Dutch electric assist trike

5. Mando Footloose: a chainless hybrid e-bike

6. Wooden bike by Yojiro Oshima

8. Is TJ Tollakson the Graeme Obree of triathlon?

9. Trimtab 3×3 recumbent trike

10. Urban Arrow- an electric assist bakfiets design

12. Rael road bike concept 2.0

14. Diesel/ Pinarello urban bike

17. I must like harebrained ideas

18. Trek Sasquatch and Sand Crawler Cruisers

19. Fast Forward powered pedals

21. City Cycle- a pedal-powered pub

23. Forzer off-road handcycle by Marius Hjelmervik

24. A hubless wheel from the past: The Black Hole

25. Mechanical doping and the future of e-bikes

As I mentioned, there were quite a few posts that were popular from 2005 to 2009 that didn't make this list. The early guest posts by Mark Sanders and Michael Downes were quite popular (as was my feature post about Michael in 2006). Posts about the Cannondale Jackknife concept bike (2006) and the JANO dual bike (2007) were among the first to be picked up by large blogs like TreeHugger and Gizmodo to really cause a spike in pageviews at Bicycle design. Joules, the electric stoker was another post that spread around the web and drove a lot of traffic back to this blog. The most viewed posts by far prior to the 2010 switch to WordPress were those from the 2008/09 "Commuter Bike for the Masses" Design Competition that I staged here at the old blogspot site. You can see the six finalists and the winner from that competition here.

Strida folding bike design by Mark Sanders

Looking back, it really has been a great ten years. Thanks to those of you who have been reading since the beginning…and to those of you who just started.

//

Subscribe to the email newsletter, and follow Bicycle Design on Facebook , Twitter , Pinterest , and Google + … and now on Instagram too!

It's that time of year again. Bike show season kicked off on Wednesday with the opening of Eurobike 2015 in Friedrichshafen, Germany. One of the big stories from the show this year seems to wireless electronic shifting. SRAM's new RED eTap system is getting a lot of positive press, and FSA is showing a prototype wireless group at the show as well. Wireless shifting has the potential to have a big impact on the design of racing/sport oriented bikes, but I'll save that discussion for another post.

Today, I want to share three interesting bikes that caught my attention as I have been browsing online galleries and following the #eurobike hashtag on Twitter the last few days. First is the Tern Cargo node. The folding bike company teamed up with Xtraccyle to create a longtail version of the Node that will retail for about $1800. Tern calls it, "a game changer if you live in a city or just want more portability from your cargo bike." They designed the bike to fit in an elevator, so you can easily take it up to a high-rise apartment or office. The option to fold is also a plus for transit riders, as it can be done with a load of cargo on the rear rack.

Shannon Evans of Xtracycle and Josh Hon of Tern on the Cargo Node. Photo credit: BikeBiz.com

German company Altinsoy Manufaktur is showing the Bees Bike, a very unique modular mountain bike with a belt drive and internal gearbox. According to a recent GizMag post:

"The bike adjusts around the rider through an integrated system of bolts and mounts. In this way, the bike can adjust to better fit your body and riding style. Of most interest is the stabilizer bar that can be swapped in for the DT Swiss rear shock, creating a fully metal hardtail in place of a springy pivoting rear triangle."

I am not sure about that feature (why not just lock out the rear shock?), but I do think the frame is interesting and I like the way the gearbox is integrated. If this is a first bike design from Altinsoy, I am looking forward to seeing its evolution.

Altinsoy Manufaktur’s Bees Bike at Eurobike. Photo credit: GizMag.com

The final bike I want to mention isn't really a bike at all. The ICE Full Fat 26FS is a recumbent fat trike that evolved from the custom trike ICE built for a ride across Antarctica to the South Pole in December 2013. The full suspension trike is built for expeditions with oversized 26 inch rims and 4.7" (front), 4.8" (rear) tires. It features a Rohloff XL 14-speed hub based drivetrain, and a 4130 chromoly frame that can be folded for easier transport to the trailhead. This is definitely not a mainstream machine, but based on the number of photos on Twitter and Instagram, it does seem to be a crowd favorite at the show.

Subscribe to the email newsletter, and follow Bicycle Design on Facebook , Twitter , Pinterest , and Google + … and now on Instagram too!

I am a big fan of Mike Burrows, and have mentioned his work quite a few times over the years at Bicycle Design. In 2012, lifelong "cycling fanatic" and engineer Karl Sparenberg of Advanced Velo Design took over production of Burrows' Windcheetah recumbent trike, and has been working on improving the materials and manufacturability of the original design. I think it's a pretty interesting story, so I am letting Karl tell it to you directly in the guest post below.

Having taken over the production of Windcheetah's a couple of years ago the design and manufacturing has taken a different tack.

Many people are already aware of Windcheetah's so I've decided not to rattle on with all the historic detail… but it goes without saying that Mike Burrows did a pretty good job 30 or so years ago when he designed it!!

But please do note that the modern iteration of Windcheetah is now a more cutting edge speed machine, incorporating advanced materials including Carbon composites and Titanium that were still prohibitively expensive in years gone by, and with that we have to move with the times and produce a 'better' machine.

When I took over the manufacture Windcheetah, to my alarm there was an Achilles heel, not with the design but the castings. These are the components that make up the frame, by bonding the aluminum and carbon tubes together onto spigots, these sand cast aluminum components could come from the foundry with flaws or voids in them.

If you could imagine ordering a 'set' of castings to make a Windcheetah frame and then having to go through the whole long winded process of post casting heat treatment, machining, drilling, tapping, powder coating and then the final finishing, only then can you proceed onto the bonded assembly with the tubing.

At any stage in this manufacturing process, from the rough sand castings to the finished component can the dreaded 'flaws’ or 'voids’ be discovered. Even worse, if the frame has been fully assembled and the sand casted part fails during testing, not only would the whole frame have to be scrapped, but it would also take out any of the other perfectly good components and tubing to the scrap bin with it. A very expensive and time consuming process as I'm sure you could imagine… there had to be a better way to manufacture these components!?

You may be interested to know, why were the sand castings failing at such an unacceptably high rate? Well, a few things really, but predominantly the foundries in the UK had to compete with the far east for business and as a consequence many of them had to shut down, leaving in short, foundries that were not tooled up for small production runs, or the necessary skills to cast such intricate shapes, as you find on a WIndcheetah. The foundry would simply credit the customer if any of the components failed. But this gesture didn't really help, when what was required was a full set of components to build a machine, not the hassle and cost implication of trying to manage the ongoing balance of the failure in certain components, while the 'perfect' odd parts sat on the shelf.

Top: CAD model screenshot and a 3d printed part (used to produce the soft mold needed for wax production).

The solution became apparent after considerable research into an alternative method of manufacturing and with massive investment into the tooling for a process known as 'lost wax' or 'Investment casting', the two terms are interchangeable but in essence the same thing

So what you see below is the result of numerous hours of redesign and CAD drawing to be able to 3D print the parts ready for soft mould production that manufacture the waxes. Now we can produce waxes this opens up the possibilities of alternative materials to Aluminum. Shortly we will be bringing to market a Magnesium version as soon as Beta testing is completed. The advantages of Magnesium or Aluminium are instantly a weight saving of third the weight.

So watch this space for an even quicker, lighter and more performance orientated Windcheetah.

For further detail contact me directly karl@windcheetah.co.uk

Wax parts for aluminium investment casting

//

Subscribe to the email newsletter, and follow Bicycle Design on Facebook , Twitter , Pinterest , and Google + … and now on Instagram too!

An earlier version of Specialized Creative Director Robert Egger's "Eff You See Eye" concept bike was mentioned on Bicycle Design a couple months ago (in a post that was also featured on Core77). At that time, the personal project bike was just a teaser, a partially assembled primer grey prototype, but now Specialized has released photos of the completed concept bike, along with more information about the design, on their Very Special Things site.

In the updated post, Egger talks about his reasons behind the fUCI project:

"It's kind of everything anti-UCI. Basically a 'hey, here's a totally different way of doing things. It doesn't fit into your box, but the people who would appreciate this bike aren't concerned with that box.' The whole thing was really just an exercise in working outside of the UCI box."

He goes on to say:

"The UCI really caters to a very small population, but there's so many other people out there who couldn't care less about the UCI. They don't follow the racing and they don't even know all the limitations that are put on bikes for the UCI riders. So, my feeling was let's design a bike for someone who really just wants to go fast on a road bike."

I won't elaborate on the design. If you are interesting in learning more and seeing additional images, you can click through to the updated post at Very Special Things. The design itself is secondary to me. What I really love about this is the fact that someone from major bike company is talking about ignoring the UCI technical regulations when it comes to product development. Regardless of your feelings about the UCI (and I have shared my opinions here more than a few times), rules that govern pro racing should not completely dictate the types of bikes that are available to the public. I completely agree with Egger that there is a huge market of people who would like to ride fast, but could care less about the UCI. Actually, I would consider myself to be part of that market, so I would love to see more speed oriented bike designs that are faster and better then the bikes in the pro peloton. As Egger says in the article, the job of a designer is "to create products people feel they can't live without." Great…and for the record I can definitely live without another 6.8kg double triangle carbon frame. There are a few innovative non-diamond frame designs out there already (mostly geared toward triathletes), but I hope to see many more non-UCI compliant road bike designs on the market soon. Even if the fUCI will never be a production model, kudos to Egger and Specialized for stirring the pot.

Photo credits: Carson Blume

//

Subscribe to the email newsletter, and follow Bicycle Design on Facebook , Twitter , Pinterest , and Google + … and now on Instagram too!

Back in the mid nineties, I remember being completely fascinated with Damon Rinard's "How I Made a Carbon Fiber Bike in My Garage" article (20+ years later, you should still check out the archive of his old Tech Pages if you never saw them, and read a recent interview with Rinard at Slowtwitch). I still enjoy seeing homebuilt carbon fiber bikes, and have posted a few reader submitted ones here at Bicycle Design over the years. Today, I want to share one more, a recent personal project by UK based mechanical engineer Richard Machin.

Richard's bike, which was inspired by classics like the Lotus 110 and Pinarello Espada, will serve as his personal time trial machine. Squeezing it in after his day job, Richard spent 8 months on the project, from the first CAD model to the initial test run.

See below for an explanation of the project in his own words.

"The main aim was to produce a light-weight frame with the lowest possible aerodynamic drag I could achieve, whilst still having the “traditional” riding position of a “conventional” bike which I consider to be much safer than a recumbent when being used on public roads. To achieve this, four main strategies were employed:

- Remove frame elements where possible

- Minimize the frontal area of remaining frame elements

- Improve the cross-sectional shape of remaining frame elements

- Shield components from the air flow by placing them behind other elements

Examples of how these principles were applied include: Removing the downtube from the traditional bike shape and inclining the seat stays to an extreme angle which both decreases their frontal area and increases their length to width aspect ratio when measured in a horizontal plane (i.e. in-line with the air flow direction). The rear brake sits nestled behind the chainset above the chainstays so it truly is hidden from the wind, not just out of sight as with some designs where they are underneath the chain stays. The front brake isn’t shown in the pictures but the intention is to get a set of forks with integrated brakes behind the fork arms. At the moment I am using a Campagnolo U-Brake to achieve the same effect.

As the bike will be used on flat Time Trial routes and velodromes only I dispensed with the small inner chain ring which also allowed me to avoid the use of a front derailleur. A small carbon fibre chain guard sits above the chain ring to stop the chain dropping off during gear changes.

Obviously when you’re going to all that trouble to design an aerodynamic frame you also want the best wheels you can find, which is why I went with a rear disc and front tri-spoke. The disc wheel has a built-in PowerTap power meter so that I can actually measure the improvement in drag compared to my “conventional” bikes."

The frame itself is a combination of aluminum (drop-outs, bottom bracket shell, head tube, seat post clamp area), and carbon fiber. The carbon fiber parts were a mix of pre-made plates and tubes cut and bonded together with the aluminum parts to form the basic shape and then the whole thing was encapsulated in several layers of wet lay-up carbon fiber for integrity. "

For more information about Richard's bike, follow his Velox Facebook page, where he plans to post further updates about the bike and its development.

(adsbygoogle = window.adsbygoogle || []).push({});

Subscribe to the email newsletter, and follow Bicycle Design on Facebook , Twitter , Pinterest , and Google + … and now on Instagram too!

Julien Delcambre currently works as a watch designer in Switzerland, but in a previous job at Scott Sports he designed a few interesting concept bikes. He points out on his Behance page that his main mission at Scott was to redesign the old Gambler (a full suspension mountain bike). He was in charge of the design and graphics for all the parts and frame.

"I was in charge of the design and graphics for all the parts and frame. Firstly the job was to create new frame with 27.5 wheels, new saddle, new links. Then I worked on the graphic elements ( colors, shapes, fonts ) to finish the complete bike."

You can see the Gambler on his project page, but the designs that caught my attention were his time trial concepts. Really interesting forms…especially the Plasma concept that is partially shown in the image below.

(adsbygoogle = window.adsbygoogle || []).push({});

Subscribe to the email newsletter, and follow Bicycle Design on Facebook , Twitter , Pinterest , and Google + … and now on Instagram too!

The Gocycle folding electric bike was first mentioned on Bicycle Design in early 2009. At the time, its clean design with a fully enclosed drivetrain seemed quite innovative. Six years later, the latest Gocycle G2 is still an innovative design, which is why it was recently awarded a 2015 Red Dot prize for Product Design (one of more than 10 design awards since it received an igus Gold Manus Award in 2006).

The G2 was designed and developed by former McLaren engineer Richard Thorpe, and he explains that the bike was strongly influenced by automotive engineering principles.

"As a designer, the end result of your work is defined by the product's DNA - the building blocks. A no-compromise mind-set in the choice of materials, production processes, and total component integration so that all parts work and fit together is what sets the Gocycle G2 apart; it has more in common with a car than a bicycle.

Materials choices and construction processes expand the possibility for a designer to come up with different creative solutions. Gocycle's fluid form is a result of my choice to work with different materials such as lightweight and exotic magnesium alloy. Using an injection metal molding process for the construction of the frame and wheels yields smooth and naturally flowing lines in the form. The weight is balanced, the power is balanced, central and dynamic from a visual perspective - and you feel this too when you ride an electric Gocycle."

Due to Thorpe's material choices, the G2 is lightweight for a folding electric bike…only 16kg (about 35 lbs). If you are carrying the folded bike up and down stairs daily or taking it onto a crowded commuter train, the lighter weight is a benefit, as is the lack of a messy exposed chain.

For more information about the G2, visit the Gocycle website, and check out this video review from Electric Bike Report.

(adsbygoogle = window.adsbygoogle || []).push({});

Subscribe to the email newsletter, and follow Bicycle Design on Facebook , Twitter , Pinterest , and Google + … and now on Instagram too!

To celebrate their 100th birthday, the Minneapolis Institute of Arts (MIA) teamed up with Handsome Cycles to bring some of the MIA's most famous masterpieces to life in the form of three art-inspired bikes. According to MIA Venture Innovation Director Hunter Wright, "The MIA is excited to partner with Handsome Cycles, a company that shares the museum's commitment to embracing the local and integrating great design, technology, and experimentation, while staying true to its core values and community. "

In order to create custom bike designs inspired by pieces in the MIA's permanent collection, including paintings by Claude Monet and Frank Stella, and a 1948 Tatra T87 sedan, Handsome reached out to a few other notable Minneapolis based designers and artisans – KNOCK, inc., TREAT AND COMPANY, Peacock Groove, and Dirt Designs Graphic. The results of the collaboration are pretty impressive… as you can see in the video below.

Art Bikes KNOCK | TREAT & Co. | Handsome | MIA from KNOCKinc Interactive on Vimeo.

See images of each of the bikes below. I like many of the details on each of them, so it's hard to pick a favorite. The bike inspired by the 1948 Tatra T-87 sedan is the one that I keep going back to though. I just love the form of the fender skirt, inspired by the car's rear stabilizing fin.

Trend site PSFK talked to Handsome's Ben Morrison about each of the bikes. Check out their post for his take on each of the three designs.

Just one last thing to point out… these bikes aren't just one off museum pieces. The limited edition 100 Year Commemorative Bikes will be available for sale (retail $1099.95) at the MIA Shop and at HandsomeCycles.com.

//

Subscribe to the email newsletter, and follow Bicycle Design on Facebook , Twitter , Pinterest , and Google + … and now on Instagram too!

If all goes well, I'll race at HPR later in the season. Then that bike retires in the living room, and I get rolling in the shop on the next racer...

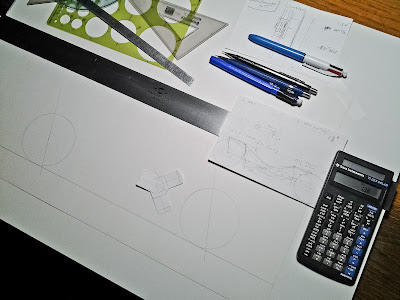

The next racer is still in the phase before "Connect the Dots" that I like to call "Collect the Dots". While working on some of the design headaches involving a belt drive primary connecting the KX500 engine to the 999 transmission, I wondered if there was a remote chance that a 999 primary drive gear system would fit, since the KX500 primary gearing is terrible for roadracing. The KX500 stroke is a lot higher, so I assumed it wouldn't fit. With the help of a few parts on hand and a few more cheap parts from eBay, the answer became obvious:

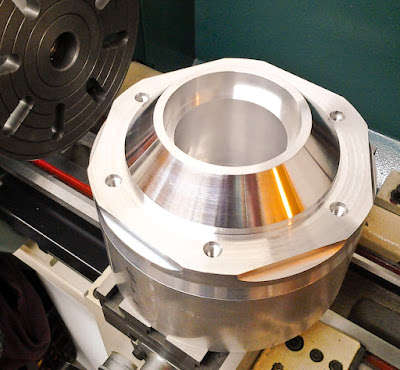

The drive side of the crank, 999 primary gear, and KX500 primary gear were promptly boxed up and shipped off to a gear making specialist in England, where a few hybrid 999/KX500 primary gears will be made. Longer connecting rods will also have to be made (The original rod/stroke ratio is not optimal for a higher revving roadracing engine). A longer crank pin will be required for my counterbalancer/inlet valve/supercharger (Yes!!!!) design. Patterns and castings will have to be made for the engine cases. Then those cases have to be machined. It'll be a lot of work, but it should be an a lot of fun.

And then there's the rolling chassis...

And then there's the ultimate question that I can't wait to find the answer: How exciting will it be to exit Pit Out, tip it hard into T3, then pin the throttle?

Glad to be alive.

The improvement in steering and handling boosted my confidence enough to register for the MRA's final HPR event for the season.Then I got a job offer in the High Plains region of Colorado. Race registration was then cancelled, due to focus on other matters. Time to sell my Englewood home (And 8' x 8' shed) and move into a much better home (With a 30' x 50' insulated 240V workshop and 27' x 31' garage)! There's a lot of romance and mythology about building bikes in sheds - it was a fun and challenging way to start - but the Rohorn Industrial Complex has outgrown that.

There is a lot of work to be finished to the shop (And money to be spent on machinery) before a lot of work gets started on the next racer. But getting this far is a huge step forward.

The rest of 2017's involvement with motorcycle racing was behind a video camera at the MRA's HPR events. Time spent at the track, as close to the action as I could get, with an old JVC GY-HM70U and GC-PX100 was an excellent experience. If you love motorcycle roadracing and want to get involved and up close without actually racing, I highly recommend working as a Corner Marshal for a season, then getting a media pass and shooting photo and/or video. I shot most of the off-bike video content in the 2017 MRA Awards Banquet video:

- Give up and find other things to do. There are Other Things.

- Design and build a competitive club racer. Not doing it would be a waste of opportunity.

- 17 x 3.5" wheels with split hub center steering at both ends. If I can steer the rear wheel, I can drive the front wheel. An overrunning clutch to the front wheel will eliminate the need for a differential. Initially, entirely machined wheels were planned, but previous generation R1 front wheels are ideal - they are very light for a production wheel, and the hub area is big enough to bore out and install a smaller universal joint in the center with a lighter machined hub. A cheap damaged wheel verified that it will work.

- 500 single 2-stroke power, with a combination counterbalancer/intake valve (My design), and a 6 speed transmission with a dry clutch. A KX500 engine (On hand) will provide most of the mechanical parts, a Ducati 999 engine (On hand) will provide most of the transmission and clutch parts (Similar to the Tul-Aris set-up), and a foundry (Not on hand - yet) will provide the cases necessary to make it all work. That will be a lot of work, but it should make a lot of power for a very small engine, with much less maintenance, tuning work, exhaust fabrication, and cost than a multi-cylinder engine.

- Very narrow triangulated steel tube chassis. Exotic construction techniques were studied with a lot of enthusiasm, but none of them had any practical appeal. The ergonomics of the first racer were excellent, as viewed from the side, but the hands, knees, and feet need to move a LOT closer together to improve safety and aerodynamics.

When? Not soon enough....

Yes, steering geometry matters at the rear wheel as much as the front. A LOT of work was done to determine which geometry works and which doesn't. Instability from weaves, and speed wobbles with just the rear wheel, is no fun. That hasn't happened to this bike, but has happened with the electric one.

The drum brake rear wheel from the EX500 worked very well for this experiment. It is red because the donor bike came with a parts bike that had red wheels - no clever or creative aesthetics involved. The wheel was sent to Kosman Specialties to have the hub bored out back in 2009. That was the only machine work for this project that I didn't perform, since the wheel didn't fit in my lathe/mill.

The rest of the machined parts came out of my Grizzly G0516 lathe/mill. I got a lot of good parts out of that machine, but it has since been sold. The next racer will need more serious machinery located in a serious shop, rather than my kitchen (Seriously!).

Yes, it is a lot of fun to show up with an exotic motorcycle, but racing is about how you ride, not what you ride. Other than some minor bodywork restoration and steering column modification, there's nothing left to do except ride it. And work on a completely new design based on the same configuration and very little else.

After those first 2 laps and an hour or so of inspection (No loose or missing hardware! No adjustments needed at all!) and introspection (Do I really want to do this anymore? The turns are where I remember them 2 years ago, but where did my sense of timing go? Do I really want to go back out there?), the doubt, confusion, and overwhelming sensory input that race tracks can provide somehow evolved into that powerful feeling that somehow gets helmets and leathers on without thinking: Must! Go! Back! Out! That is a really good feeling!

The next 2 laps went a lot better. Even though I haven't ridden it (Or anything else) in 2 years, I still instinctively slid over on the seat to hang off into the corners. That isn't necessary anymore, since the 2WS system reduces lean angle a lot more than hanging off. The linked braking system is a huge improvement over the old system. Hard braking is drama free, as is trail braking into corners. Great brakes and steering systems might not sound too useful when they aren't being used properly, but they do wonders for improving confidence in the bike.

The last 3 laps were just a lot of fun trying to use what I learned earlier in the day. No lap times were recorded, but I'm looking forward to learning a lot more. The last MRA race of the season is at High Plains Raceway, 17-18 September.

The racer was finally assembled enough to fire it up and ride it this afternoon. The test ride was only a 1st gear lap around a nearby parking lot, but it went very well - well enough to look forward to a test & tune day at the track. And if that goes well, we go racing.

Some details need finishing, like securing the wiring and lots of safety wiring. The nose section was structurally repaired, but not cosmetically finished - I didn't want to delay the testing any further.

This has taken a lot longer than expected, but it has been worth the time and trouble.

No, it won't break any lap records or even get close to the podium, but I'm confident that the next and better racer will easily do that. The next and better racer will share the same configuration and fundamental dimensions, but little else. A lighter steel or aluminum ladder frame would be easy to make, but it still wouldn't be light enough. Exotic motorcycle frame design and construction techniques really don't transfer to this configuration, but there sure seems to be a lot of potential with advanced Formula car methods. Exotic fabrications using aluminum honeycomb sound amazing, even if those are also obsolete. What could be more intriguing that bringing motorcycle construction from the biplane era to the early Cold War supersonic jet era?

Frame design can be described as a structural connect the dots puzzle. It is fun to imagine really exotic solutions, and even more fun to talk about. Material expense, repairability, maintenance access, and ease of fabrication reduces the fun quite a bit. The solution that increases the probability of getting on the starting grid, going faster, and finishing ahead is the most fun.

Much of the trouble getting any work done on the racer has been the result of having a screw loose. No, that isn't comfortable. That is also getting removed soon! Progress on the racer should happen a lot faster afterwards. Faster is always better.

See you at High Plains Raceway soon....

More power with potential for a lot more power, a lot less weight (Goal: 265 lbs), a much narrower rider position (Much more aerodynamic and safer as well; the rider's squishy and crunchable bits go inboard the frame's perimeter this time), and loads more traction sound like my idea of fun. If all goes well, 2016 will see the current racer back on the track and construction started on the next racer. No idea what year it will be finished.

By the way - ever compare a four stroke street bike wiring harness to two stroke race bike wiring harness? Wow!

Oh, yes - the four stroke engine design can wait for another year. Or decade. It is still pretty neat...

While 2014's racing results were dismal, I'm still very optimistic about lowering my lap times a lot and picking up a few places. Not getting lapped would sure be cool, even if I do learn a LOT from the fast racers. And if you think watching them from the stands (Or better yet, while cornerworking!) is exciting, imagine the view from the track! But there's much to work on, on both my riding and the racer, before better finishes happen. It'll never get on the podium; that's for the next bike with a better rider.

Which means that, yes, I should be working on the racer instead of hypothetical engine models. Crash damage needs to be repaired, and that new rear suspension system still needs finishing and installation. I'm still hoping to have it done before the end of the 2015 racing season. But my biggest source of enthusiasm and motivation is the next racer; this racer has given me the confidence to make it worth the time, trouble, and expense. In the mean time, the door that leads from my desk to the shed has been upgraded to lower my house exit times by at least .2 seconds. No chatter problems, either.

I'm very happy to report that my foot is healing rapidly. The big goofy post-op boot has been off since early November. The crutches haven't been touched since the Christmas holidays. The cane only gets used on evenings of rougher days and to help make a point while yelling at kids to get off my lawn. I'm just left wondering whether or not my right foot will need a racing boot that's 3 sizes larger than my left foot. Either way, it would be a shame not to find out this year...

Top photo: Jim Browning, Rocky Mtn Photos